Strength in Numbers

For years a limb abnormality kept Evan Bonazzola from working out – until a team of student engineers created a solution that led to a day he won’t soon forget

By Richard McNeal

“Hey Todd, guess what day it is?”

That’s the challenge student Evan Bonazzola playfully presents to physics professor Todd Curtis as the pair stand together in the weight room of the Hadlock Student Center on a Friday afternoon.

It’s mid-April, and there is a cacophony of activity in Hadlock at the moment: students are working out, clanging weight machines and plodding on treadmills; a group is playing basketball downstairs, the piercing squeaks of their high tops and thumping dribbles punctuating the atmosphere in familiar juxtaposition; the card-swipe gates at the front entrance offer the occasional electronic de-ding!, inevitably followed by an audible welcome from the front desk attendant; and then there’s the student-curated Spotify playlist sounding throughout the facility.

Despite the surrounding din, three engineering students – looking out of place in their street shoes and blue jeans – are huddled together, focused on making a few final adjustments to a prototype prosthetic device they’ve designed specifically for Bonazzola.

Also an engineering student, Bonazzola was born with symbrachydactyly, a condition characterized by limb abnormalities. His left hand is underdeveloped and prevents him from accomplishing tasks in the same way someone with two fully developed hands might – say, working out at the gym. Bonazzola boasts a refreshingly positive perspective, though, often leveraging his limb difference to make all the stereotypical hand jokes one would expect. If a friend asks him to help move something, for instance, he mischievously replies, “Yeah, I can give you a hand.”

For the most part, Bonazzola can creatively address any issues his smaller left hand presents – which include daily tasks like tying his shoes. Although there are a few activities – like playing the piano and rock climbing – he hasn’t quite figured out yet, there is one pursuit in particular that has loomed large in the back of his mind for several years: pull-ups.

In high school, Bonazzola had to attempt pull-ups for a required physical test. When he struggled to complete one and fell, the P.E. teacher didn’t hesitate asking for the next person in line. Not only that, at the request of his gym instructors, Evan found himself jogging around the track instead of participating in the day’s scheduled activity on more than one occasion. Ever since, he dreamed of one day conquering the weight room.

“Hey Todd, guess what day it is?” The professor isn’t sure. He looks at his watch; he can’t recall the date.

Curtis is one of the faculty advisors for the Servant Engineering program, a two-semester course in which all junior engineering majors enroll. The purpose of the course is to demonstrate how engineering skills can be used to help others, so students are placed in small groups with a faculty advisor and tasked with working on a service-based engineering project during the year. Recent projects have ranged from the immensely practical (designing mirrors for mobility devices) to the extremely involved (developing methods for teaching microfluidics in the public school system). Though diverse, all projects share a common theme: human-centered design, that is, focusing on client problems that actually exist rather than considering problems personally exciting to the engineer.

Two years ago, Curtis decided he wanted his groups to begin working in the area of prosthetics. According to the professor, an abundance of highly developed prostheses perform 90 percent of daily tasks effectively, but there is a narrow gap of activities that even typical prostheses do not accomplish well. What’s more, nearly 60 percent of people with missing upper limbs do not use prostheses simply because they are expensive or uncomfortable.

“We wanted to look at that need and look at how we can come up with task-specific, low-cost prosthetics,” he says.

As a result, Curtis’ three-student Servant Engineering team worked with Bonazzola to develop a prosthetic “hand” that would allow him to exercise in Hadlock, specifically using free weights and doing pull-ups.

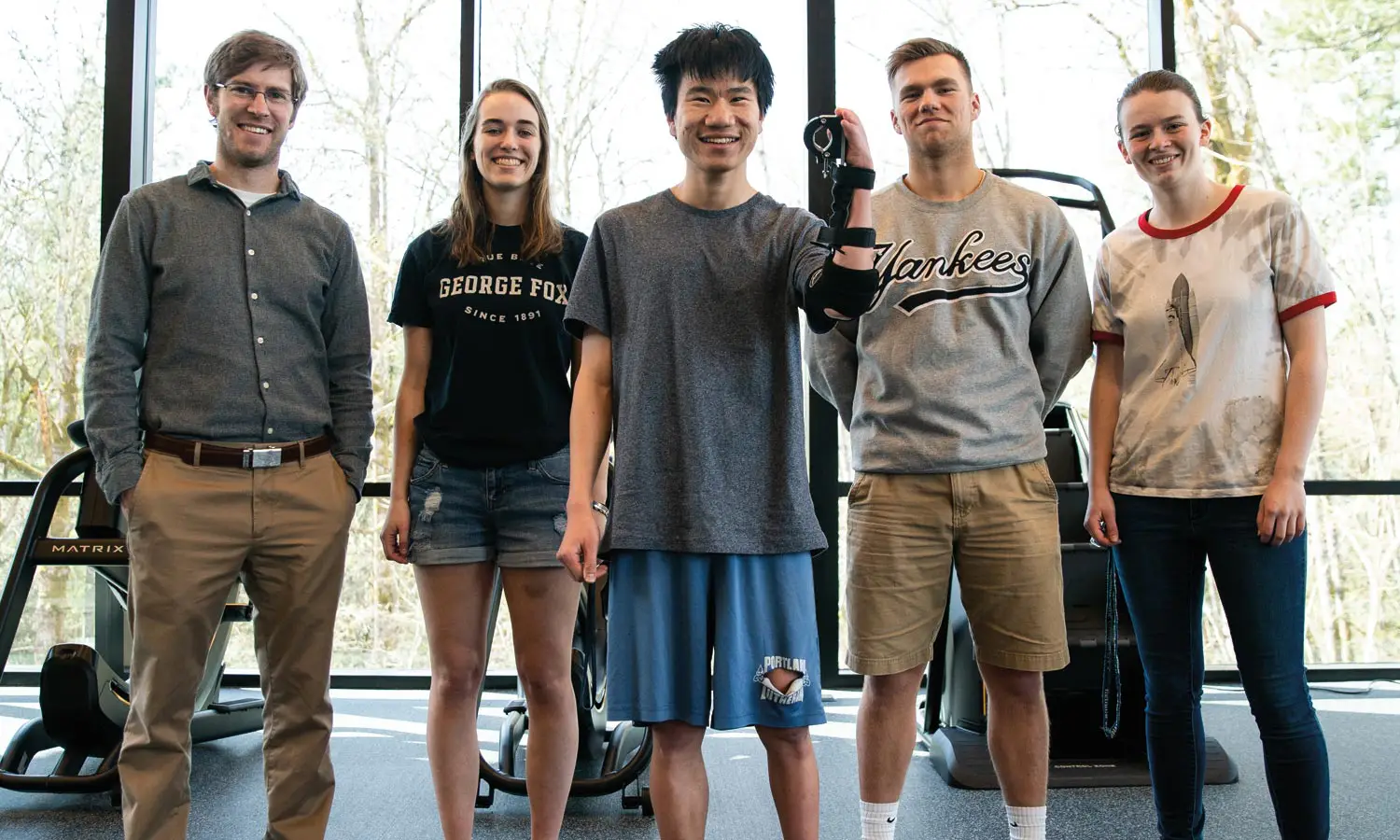

“Hey Todd, guess what day it is?” The three engineering students – Gabi Lorenzo, Madi Jones and AJ Atherton – overhear Bonazzola’s question and momentarily stop their conversation. For this engineering team, at least, the day marks a significant milestone in the work they have done to help him achieve his goal of weightlifting and doing pull-ups. After hours of research, interviews, brainstorming (a process they affectionately refer to as “PAINstorming”), and countless iterations and adjustments, they are finally ready for Bonazzola to test out their prototype prosthesis.

One of them invites him over: “Here, try to put this on.”

He slips the brace over his left arm using his right hand. Atherton asks how it feels. Bonazzola struggles locking the carabiner that connects the elbow brace to the wrist brace – it’ll get easier with practice, Lorenzo assures him. He wonders how the elbow brace is supposed to fit; Jones says whatever feels comfortable.

After a couple of minutes, the prosthesis is secure on Bonazzola’s left arm, and everyone turns their attention to the pull-up bar. There is a thick foam pad already set up beneath the bar, no doubt serving as both step stool and safety precaution. Bonazzola hops up, decidedly grips the bar with his right hand and guides the C-hook around the bar with his left. The team watches him from behind. Two pull-ups later, they are all smiling in awe. Bonazzola is smiling, too. He does a couple more pull-ups. Someone utters, “Oh, wow.” And another, “That’s so cool.”

Later, Bonazzola describes the feeling of those first pull-ups: “It’s like being able to run after only being limited to walking, or like running with weights and then having them suddenly fall off.”

Lorenzo captures what the engineers felt: “We never thought he’d be able to do it. We never thought that our design or our bracing system was going to be able to withstand a pull-up. And so the moment he actually did a pull-up, we were like, ‘Wow, that actually worked!’”

After testing the prosthesis on some other workout equipment, the group migrates to the rack of free weights on the south wall. Evan secures a 12.5-pound dumbbell to his left hand using the clamp attachment, then grabs a second 12.5-pound dumbbell with his right hand and begins alternating bicep curls. A brief smile flashes across his face as he lifts his left arm. The heaviest weight he has ever lifted with his left hand before this day was two pounds. And since that first test, he has lifted as much as 25 pounds.

Finished with the free weights, Bonazzola removes the prosthesis. He hands the brace to the student engineers who begin chatting about some minor adjustments they need to make in the next week or two. He approaches Curtis.

Hey Todd, guess what day it is?” The professor comes up blank, so Bonazzola delivers the answer, capturing the significance of all that has just transpired in a way only he can: “It’s Evan-Gets-A-Hand Day!”

If you have a limb difference and are open to exploring solutions with a George Fox Servant Engineering team, they’d love to talk with you. Email Todd Curtis (tcurtis@georgefox.edu) for more information.

Featured Stories

Bruin Notes

- University Explores Healthcare Partnership in Southern Oregon

- Alumni Plaza Celebrates Legacy of Bruins Past and Present

- The Class of 2019 moves on to new careers and grad school

- Faculty Members Honored as Top Teachers, Researchers for 2018-19

- New Facility Focus: Hadlock Student Center

- Community Mourns Loss of Longtime Supporter Ken Austin

- In Print

- Recent Recognition

- New Residence Hall on Track for Fall 2019 Completion

- Sports Spotlight

- Teaching Theology in the Age of Netflix

- University Recognized for Value, Innovation in Latest U.S. News Rankings

Alumni Connections

- Tolon Pursues Her Passion for Law

- Life Events

- George Fox Grads Find Community and a Mission Through Socially Conscious Fashion

- News, by Graduating Year

- Rodriguez Recognized as 2018 Oregon Elementary School Principal of the Year

- René Makes Big Impact as a Big Brother

- Minthorne Leaves Legacy of Leadership, Generosity

- Send Us Your News